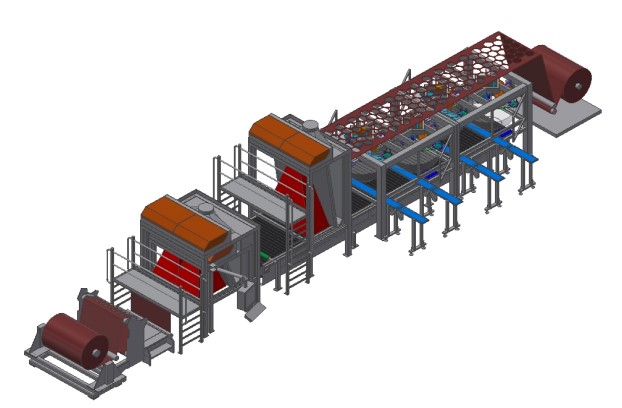

MultiCutter Multistage 1600

The ZennaLaser MultiCutter MultiStage 1600 is a specialized laser cutting line for the production of large quantities of discs and sheets with multi-holes. The line is highly efficient as it combines the flexibility of quick product changes with the ability to cut any hole pattern in any shape on full web material, with a maximum width of 1600 mm. The MultiCutter MultiStage is the laser cutting line with the highest capacity on the market for producing discs with multiple holes. Cutting in two laser stations with multiple parallel high-power lasers is combined with patented M2-belt transport and advanced collecting robots. This combination of two laser stations, high laser power, robots, and camera (vision) systems, makes the MultiCutter MultiStage 1600 the best laser line on the market.